The second day of our last week’s Kia road-trip to Poland (Euro2012) was certainly one of the highlights of the whole 6-day journey.

After spending a day in the beautiful city of Wienna, we drove our brand-new Kia cee’d further towards Slovakia where we were scheduled to visit Kia’s state-of-the-art manufacturing plant.

The Slovak factory is Kia’s only European manufacturing plant.

Five other company plants are located in South Korea, two in China (with one additional being under construction) and one in the USA.

Located in a vast industrial complex extending over 223 hectares in Zilina (the largest town in hilly North West Slovakia), the plant employs around 3,500 people with more than 95% of all being the citizens of Slovakia.

The carmaker’s European facility utilizes a large number of the state-of-the-art car manufacturing technologies including more than 410 robots.

Producing at full capacity, the plant can churn out around 300,000 new Kia vehicles per year, or approximately 100 units per employee.

Kia vehicles produced in Zilina

The 1,2-billion (Euro) Zilina plant produces three popular Kia vehicles: the new Kia Sportage crossover, Venga mini-MPV and the all-new ceed 5-door hatchback.

Kia’s plant is also running a trial production of the cee’d Sporty Wagon, which is scheduled to go on sale in Europe this autumn.

There are also plans to start the production of the 3-door Kia pro_cee’d sometime around new year if not earlier.

The all-new Kia pro_cee’d is expected to make its official public debut at the Paris Auto Show in September, while sales are rumored to commence in the first quarter of 2013.

Kia Slovakia factory production milestones

The highly-advanced Kia plant began operating in September 2006 roughly two years after the signing ceremony with the Slovak Government to authorize officially the construction of its very-first European plant.

Since late 2006, the Kia factory achieved the following production milestones:

– production of 100,000th vehicle (September 2007)

– production of 300,000th Kia vehicle (September 2008)

– production of 500,000th vehicle (December 2009)

– production of 700,000th vehicle (November 2010)

The most significant production landmark was achieved in just over five years after the factory opened its doors and that was when a 1,000,000th vehicle rolled off Kia’s Zilina plant.

The 1-millionth vehicle was a white coated Kia cee’d Sporty Wagon which was later donated to the Slovakian children charity, called the Red Nose Clowndoctors.

Kia factory shops

Kia’s manufacturing plant in Europe consists of:

- press shop

- body shop

- paint shop

- assembly shop

- engine shop

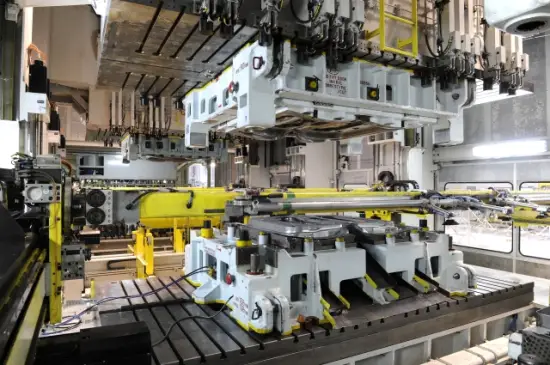

Press Shop

The whole production process of a vehicle begins in the press shop which features two main press lines that can produce more than 67 various panel types. One panel is pressed within every 20 seconds, while the total production capacity of the Press shop is estimated at around 5,000,000 panels per year.

To ensure the highest quality of the manufactured car body parts, each panel is checked in detail by using Kia’s unique 3D optical inspection system and their quality inspectors.

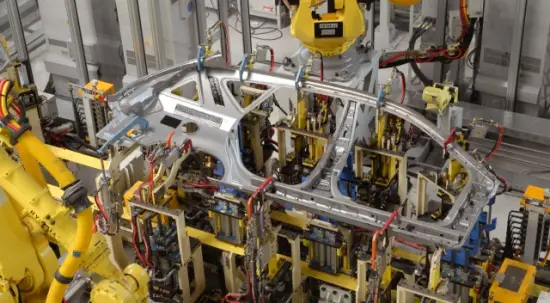

Body Shop

The production of a car continues in the body shop, where the car bodies are made by putting together and welding of sub-assemblies such as floor, left and right side structure, and roof assembly.

The welding automation ratio in the Body shop is 100%. There are more than 320 robots used for welding and processes of loading and conveying of car parts.

The possibility to simultaneously manufacture 5 different car models on the same production line is one of the most important feats of the body shop.

Paint Shop

From the body shop, the car bodies are moved into the paint shop via conveyor system with a total length of 7,5 km!

Each and every car body goes through various surface treatments to obtain its final color.

The body shop also features a unique rotation dipping system which ensures that the protection substance reaches even the most inaccessible body parts.

- Jump to Kia Sportage specs

Assembly Shop

Assembly shop is the final stop within the car production process at Kia’s plant in Zilina. The assembly shop is also the largest of all production halls within the plant. The hall is nearly 450 meters long and has a size of 100,000 m2 .

More than 1,000 employees who work in the assembly shop are responsible for installing the cables, minor interior and exterior car parts, front and rear glass, seats, wheels and other car components.

Engine Shop

Kia is the only car manufacturer in the region that produces engines on it’s own, rahter than importing them from other locations. The company runs two engine shops in Zilina which produce both, petrol and diesel engines with displacements of 1.4L, 1,6L, 1,7L and 2,0L.

The engines are fitted to all Kia cars produced in Zilina as well as exported to Hyundai’s manufacturing plant in Czech Republic (about 60 km away from the factory), where Hyundai produces the i30, ix35 and ix20 mini-MPV models.

I presently own a 2010 Kia Soul plus and am very pleased with it. I heard that the paint spec’s for all Kia’s are the worst in the auto industry. Is there any truth to this statement? I would like to trade up to a Kia Optima, but at a $28,000 cost, I don’t want the worst paint in the industry at this price. Please reply. Thanks Mike

I would imagine the Optima (made in Georgia) would have the same paint process as the Hyundai Sonata (made in Alabama). The Hyundai Sonata has better paint quality than some Mercedes vehicles. I would say whoever told you that about Kia’s paint is blowing some serious smoke.

Greg is so right. You have a lot of HATERS out there right now. I got BMW Owners telling me not to buy the K9 if I can’t afford a 6 series get a 3 series and I had to tell them off HARSHLY that I would buy the Optima fully loaded and still have 2 times more car than a base BMW.

I don’t think there is a dam thing wrong with the Kia and Hyundai paint process. If they have 1 FLAW the color selection is too basic there are not enough OPTIONAL UPSCALE colors in the palatte and that should be addressed.

We are going to Hungary and Slovakia on holiday later this month.As the proud owner of my second Kia Rio,I wonder if the Kia factory in Zilina does tours,as Zillina and its surroundings are one of the places we intend to visit.

The factory looks amazing and I think a tour would be of great interest.

They do have tours in Kia’s factory in Zilina!! Enjoy your visit!

Thanks for the info himi…..Do we need to book up with them or is it regular,daily tours?

I think it would be wise to call them ahead of your visit and schedule an exact tour date and hour. I can provide you contacts, just send me an email: [email protected]

email sent Himi…look forward to hearing from you.

Sirs,

I am in Portugal and my Kia Cee’d SW 1.6 CRDI TX 128 (Vin: U5YHN816AEL061551) came from your factory.

I collect diecast models of all my cars and can not find any where one of it.

My wife also as a Kia Picanto 1.0 TX (no rooftop) and can not find either.

Do you have them?

Regards

Diogo Vasconcellos e Sá

Hi,

I am looking for 2 Kia diecast. Kia Cee’d Sw black from 2013 and Kia Picanto Tx 1.0 red from 2008 without roof top.

Do you have them? How much? Please send photos and scale of diecast models.

Regards

Diogo Vasconcellos e Sá

I have bought a black 2007 gs picanto for my first car and I would like a diecast model to remind me of passing my test in it. Any info would be really appreciated. Thanks

I have a Kia Cee’d 2015 HB in Alexandria Egypt, The car is broken down since October 2015, the car was flooded with water due to the heavy rains. I am searching for some parts like Body Control Module & Receiver BCM 95400A2142 , Cluster Assy Instrument 94003A2043. I went to Kia agency in Alexandria Egypt, they do not have the parts in addition they want to charge me the third of car price to bring the needed items within 2 month.

If someone can guide me from where i can buy those parts, i will be grateful.

I have here in Finland a KIA Ceed 2007 (1,6 petrol engine) 100 000kms.

The car is top quality.

The only problem so far are the rear brakes. The brake pads get stuck because of corrosion at the tips of the pads. There is not enough play between the guide grooves and the pads. New pads needed a little filing to prevent seizing again.

Brake backing plates were badly corroded and had to be replaced too. They should be better coated in production.

I am doing research on the 2006 Optima LX I purchased last year and the VIN indicates this plant as the production point, but I do not see Optima’s listed as being made here. Were they produced here in 2006 or is there a problem with my VIN#?

I only have one complaint about the car since I’ve had it. Not being able to top off the tank because it messes with the fuel system or pump. After purchase, I fixed a few issues that the previous owner had neglected and now it drives great. Its stylish, comfortable and great on fuel… very happy with it.

I need some help. I totally enjoy my KIA Sportage 2.0 AWD. In 5 years the car completed 103735 kms without any problems…but now some strange squuicking nosies are heard from the rear right wheel well. The accredited KIA service cannot find the cause. I am now turning to you for possible assistance in pin-pointing the source of the trouble. Also have a look at the Face Book entry: KIA Sportage Owners Club of Slovenia…you might find it interesting

we will visit the town zilina at the end of the month.

is there a tour in the factory that we as a family can join ?

if tere is a tour how long is it ?

hello

i have a problem with my heated seats amd i am looking for this:2282808 JD WARMER UNIT ASSY. if you have it i would like to tell me the price so i could order it.

thank yoy